Classification and Setpoint Management for Rod Pump Optimization

Introduction: Rod Pump Challenges

Rod pump is the most common artificial lift system used to provide adequate support to a well when the natural flow of a reservoir is not strong enough to push oil to the ground. However, this type of system is subject to failure and downtime due to environmental conditions, mechanical wear, and other various critical conditions. Maintaining and optimizing these systems is one of the core activities engineers and techs are asked to perform on a daily basis, in an attempt to balance lifting efficiency and maximizing production. Optimizing a high count of wells can be a challenging and difficult job to complete when depending only on human expertise.

To solve this problem, Ambyint provides different models of machine learning and artificial intelligence algorithms to complement engineers and technologists. These algorithms create a workflow improvement to focus on what is most important by allowing the machine to take on repetitive tasks, while engineers focus on delivering additional optimization to wells.

Optimization Methodology & Workflow

Despite the differences in horizontal development and vertical legacy well context, industry best practices to traditional rod pump optimization around efficiency, and thus profitability, have a consistent logic and methodology.

First, wells are diagnosed as Overpumping, Underpumping, or Dialed-in. Second, based on the categorical classification, a consistent remediation workflow is applied based on the available parameters that increase production or lower the number of damaging strokes into the system.

The primary daily operational parameters to optimize rod pump wells are on/off time, SPM, and pump fillage. Following the Pareto principle, these levers represent the majority of the value-added changes that an engineer or tech uses to optimize wells. Thus, the third and final step is to apply a change to the control system (POC, VFD, timer), and observe the before-and-after to judge success.

Ideally, this workflow is performed for every well on a regular basis. However, this involves significant time and resources to accomplish, and even when done daily, can still neglect over 99% of the strokes put into a system during a well’s run-life. The reality is that field personnel have too many wells, too little time, and not enough of the right data or technology to enable a step-change in profitability.

ASPM: A Data Science Learning Model

Ambyint’s Autonomous Setpoint Management (ASPM) solves the industry challenge and uses physics-based well optimization inputs and workflows that are brought into a continuously evolving machine learning model to optimize well setpoints autonomously. The goal is to implement this big data framework in a production optimization setting, to provide data science context to the pilot results.

The Ambyint Infinity Optimization platform identifies unique instances of historical data, called “patterns”. Each pattern is defined by the unique combination of a downhole location and an end date-time, where the end date-time represents the end of a fixed period of time. Adequate time resolution for the patterns is obtained by choosing the end date-times to occur every two hours (on the even hours UTC time), but there is nothing in the method that requires or restricts this resolution.

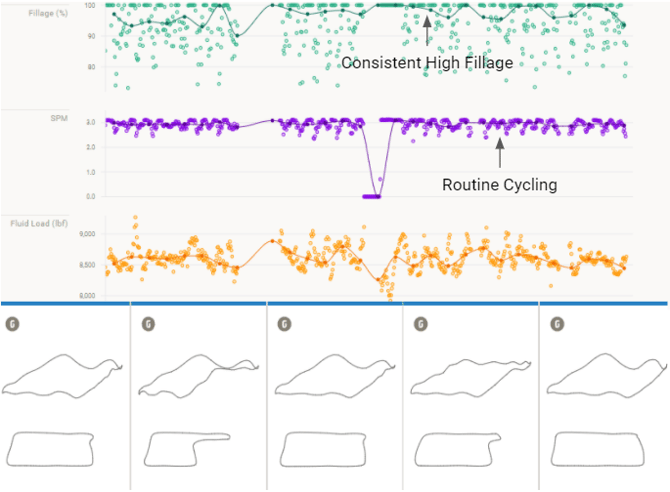

The software system collects historical data from the database for each pattern, consisting of the downhole location along with data collected and analyzed on a continuous basis. The database is built based on human expertise and knowledge labeling patterns such as Overpumping, Underpumping, Dialed-in, or Uncertain. Historical data is retrieved as multiple values for each quantity where each value is marked with a timestamp. Data retrieved includes, but is not limited to: Strokes Per Minute(SPM), fillage, percent plunger fillage as provided by the Pump-off Controller (POC), fluid level analysis, status codes and running status.

Once the historical data is collected, the software calculates feature values from the retrieved data for each pattern. All calculations summarize only the entries within the particular pattern. For example, SPM uses SPM Count, SPM Max, SPM Mean-simple arithmetic mean, and SPM sample variance. The software system then combines classifier model training, cross-validation, and hyperparameter optimization to determine the best classifier model.

Training is initially performed on the labeled historical patterns. The software system trains a single decision tree as the classifier model and limits the maximum depth of the tree to avoid overfitting the training data. The maximum depth is the only hyperparameter. The system weights the classes to balance the training and validation data by giving more weight to the under-represented classes. The program uses the F(0.1) score to heavily favor precision over recall to avoid false alarms. This includes only the Overpumping and Underpumping classes in the F score, since these are the only two classes that lead to a speed change recommendation.

Finally, the trained classifier model is applied to classify recent well data. Expert labels are then obtained for that data. If performance is unsatisfactory, changes are made and the steps are repeated. The misclassified patterns are reviewed to determine if the patterns share common properties or attributes that can be quantified as new features. If so, such new features are added to the feature set. Below is the full list of current features with their relative importance in classifying the training patterns.

ASPM Classifications: Overpumping, Underpumping, Dialed-in, Uncertain

The goal of ASPM is to achieve a Dialed-in state. ASPM works to provide maximum fluid production with minimum energy consumption and mechanical wear, achieved by setting the pump speed to an optimal speed that matches pump fluid production with reservoir inflow. If the pump speed is too high or too low, the well is Overpumping or Underpumping.

Overpumping: The pump condition of Overpumping occurs when the pump speed is higher than the optimal pump speed. Compared to operation at the optimal pump speed, energy consumption and mechanical wear increase with no corresponding increase in fluid production.

The ASPM model works similarly to how a subject matter expert optimizes a well. The model looks for severity and frequency of cycling (on/off or max/min), low fillage, low fluid levels, high loads that deviate from an optimal state. Unlike a manual process, the model also takes this physics-based data and creates derivative data that has important features to determine the classification.

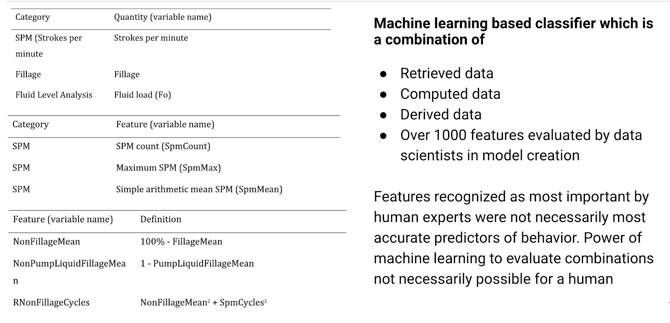

The output of the model is dependent on the device to which it is connected. In the example of a POC with an overpumping well, increasing the idle time set point is the primary lever we move to bring the well back to Dialed-in. The model works best when POC fillage and consecutive pump-off stroke set points are set consistently across all wells according to industry standard best practices. Verification of the overpumping classification is observed in the dynamometer cards. An example of Overpumping state is shown in Figure 1 below.

Underpumping: The pump condition of Underpumping occurs when the pump speed is lower than the optimal pump speed. Fluid production is increased by increasing the pump speed.

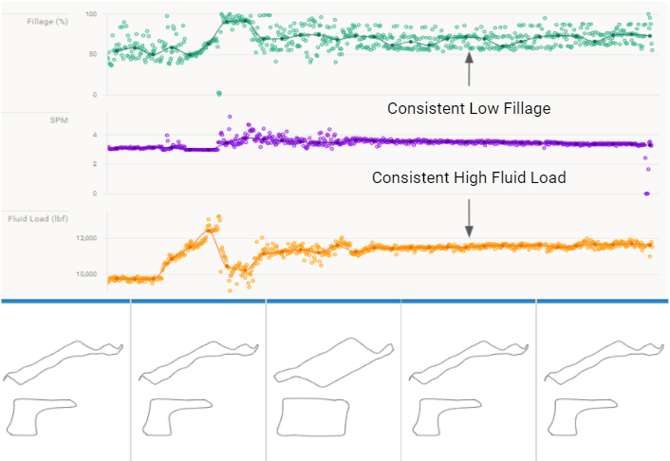

The ASPM model works similarly to how an expert optimizes a well. The model uses similar parameters to Overhumping classification. However, the model looks for a lack of any severity and frequency of cycling (on/off or max/min), high fillage, high fluid levels, and low loads that deviate from an optimal state. Verification of the underpumping classification is observed in the dynamometer cards. An example of Underpumping state is shown in Figure 2 below.

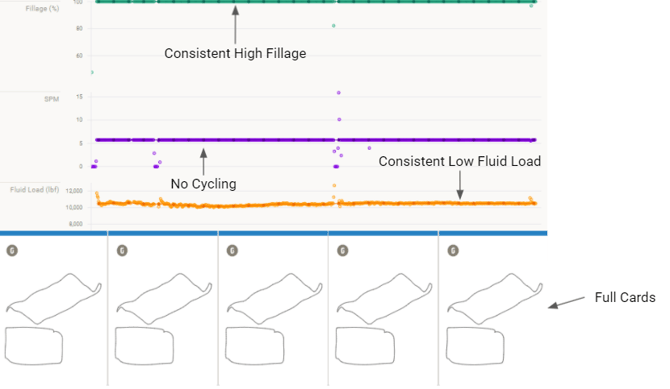

Dialed-in: In between overpumping and underpumping is a Dialed-in state. The model looks for a balance. There is routine cycling with consistent high fillage, and good fluid load and levels ensuring that pump displacement is matching inflow. Verification of the Dialed-in classification is observed in the mixture of full and pump-off dynamometer cards. An example of a Dialed-in state is shown in Figure 3 below.

Undefined & Unclassified: When the well exhibits behaviors and data signals that do not fall squarely into an Overpumping, Underpumping, or Dialed-in state, we generate a fourth classification of Undefined. This may occur when a well is at the boundary between dialed in and overpumping or underpumping. Other reasons the model will generate an uncertain classification are when the well has a high percentage of downtime, when it is offline due to failure, or a communications loss onsite where there is not enough data for the model to analyze. Additionally, the POC setpoints may be set not accordingly to recommended best practices and provide an uncertain classification due to conflicted signals. When we collect a significant number of “Other” edge cases, we initiate a retraining of the model with in-house experts reviewing and labeling those cases correctly.

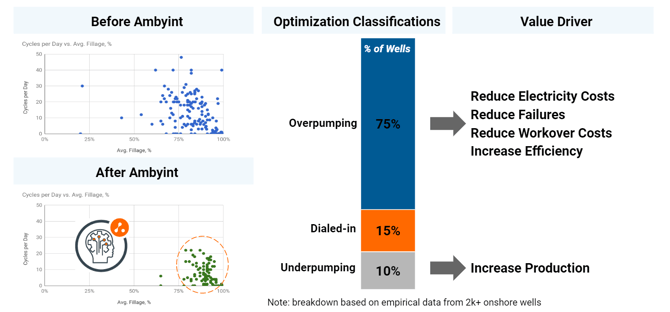

An example of before and after ASPM pilot results is shown in Figure 4 below. The data set represents a large E&P who uses Ambyint’s ASPM learning model to improve well optimization and has achieved increased production rates, reduced failures, reduced operating costs, and electricity costs.

Figure 1: Overpumping Classification - Consistent Low fillage, Consistent high fluid load, Pump-off/Gas Interference cards, Pumping faster than reservoir inflow

Figure 2: Underpumping Classification - Consistent high fillage, Consistent low fluid load, Full cards, No Cycling, Pumping Slower than reservoir inflow

Figure 3: Dialed-in Classification - Full cards with a mix of pump-off cards, Routine cycling a few times per hour, Consistent high fillage, Pumping rate equaling reservoir inflow

Figure 4: ASPM Classification Model: AI-powered setpoint management & optimization improves well outcomes

Asset & Production Protection

Ambyint’s ASPM algorithm represents an improvement in terms of asset and production protection when compared to conventional human-managed setpoints, which typically involves trial and error. The approach that has been adopted creates guardrails for both safety and certainty of implementing a setpoint change on a customer’s behalf, as well as quicker identification of outliers where employees can diagnose issues.

The ASPM algorithm, now on its fourth production iteration, has been running live for over two years operating hundreds of wells in various basins and well configurations. The model generates a probability associated with each classification setpoint recommendation (or automatic setpoint implementation). The algorithm will only generate a recommendation or make a change if the model has a high level of confidence (currently set to 60% or higher) in the accuracy of the overpumping or underpumping classification and associated setpoint recommendation.

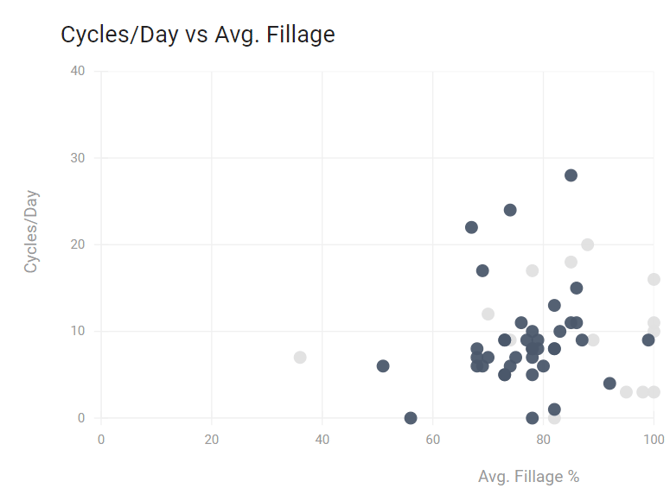

Figure 5: Example: Cycles vs. Avg Fillage - Overpumping classification → lower fillage high volatility, Underpumping classification → higher fillage, low volatility. Note these are general heuristics, and does not account for all factors in the model.

The Platform sends recommendations to customers for a particular well on a seven day schedule. This schedule was thoughtfully selected for two main reasons. First, due to the fact that a rod pumping system is a highly dynamic system, adequate time is required for the system to stabilize before higher algorithmic certainty can be achieved. Secondly, testing an algorithm is an exercise in trust building and change management, particularly during a customer evaluation of Ambyint products and services. In order to avoid overwhelming users with high volumes of recommendations to audit, weekly frequency was agreed between Ambyint and proof-of-concept customers to represent a reasonable balance between user recommendation review time, model certainty, and frequency of setpoint changes.

Additionally, the algorithm follows a systematic approach of implementing minor changes to a single variable, observing changes in system dynamics, then re-evaluating. As outlined above, this process is accomplished by allowing a few days in between recommendations to observe how the system responds before allowing the implementation of additional changes. Setpoint changes are carried out in increments of 0.2 SPM (SPM in case of a VFD) or 10 minutes (in case of a POC or motor well configuration). This significantly reduces the risk of production loss or swings in system performance which may result from exceeding the “optimal” system setpoint.

Ambyint requires all customers to provide system Safe Operating Parameters (SOPs) and work collaboratively with customers to standardize SOPs. Standardizing SOPs serves as a guardrail to prevent any changes outside the range specified by the customer. This approach allows the algorithm to safely and reliably deliver systematic performance improvements while protecting customers’ equipment and production volumes.

Similar to human optimization of wells, the algorithm does not provide a 100% guarantee of performance impacts, including production volumes. The algorithm operates based on statistical models, which means it is not possible to achieve 100% accuracy. The ultimate goal of the process is to achieve an outcome where the winners (performance and/or production improvement) will significantly outnumber the losers. To-date, this outcome has been validated across thousands of operating wells and numerous operators across multiple basins.